|

|

|

|

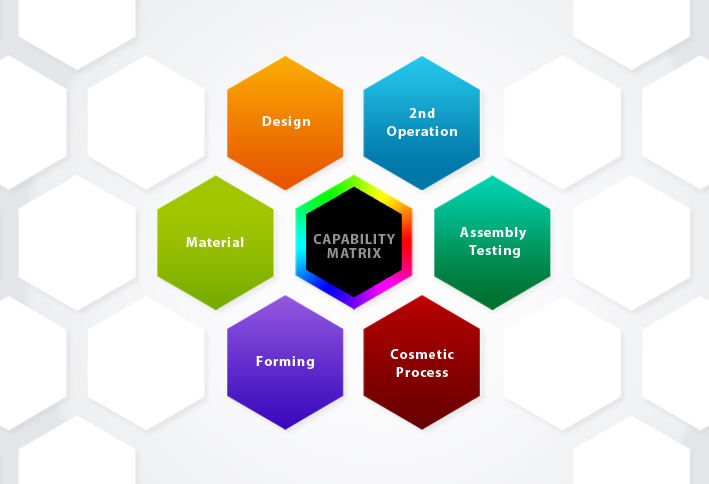

| To meet customer demand for multi-directional design , catcher integrated different manufacturing process, which can be used in a variety of housing products for the special surface treatment and texture. Catcher continuously construct a "full process matrix", showing the most valuable product, including application of software analysis, material selection recommendations, forming engineering methods discussion, a variety of secondary processing equipment, surface treatment capabilities, professional packaging group and test equipment. |

|

| Design |

Material |

Forming |

2nd Operation |

Cosmetic Process |

Assembly & Testing |

CAD

|

Aluminum

|

Die casting

|

CNC Machining

|

Powder Coating

|

Sub-Assembly

|

| CAE |

Magnesium |

Stamping |

Laser processing |

Liquid Painting |

Function Test |

| CAM |

Titanium |

Extrusion |

Rust Proof |

Anodizing |

Noise Test |

| |

Stainless |

Forging |

Chemical Etching |

Laser Etching |

RF Test |

| |

Steel |

MIM/CIM |

Tumbling |

Electroplating |

Environmental Test |

| |

Zinc |

Plastic |

Lapping |

Hydrographic

Printing |

|

| |

Copper |

Injection |

Blasting |

Thermal Transfer Printing |

|

| |

Plastics |

|

Brushing |

Electrodeposition |

|

| |

Glass |

|

Diamond Cutting |

Physical Vapor |

|

| |

|

|

|

Deposition(PVD) |

|

|

|

| |

|

|